HAND BUILT IN

Salt Lake City, Utah

Salt Lake City, Utah

Our wheels are hand built by our team of professionals in Salt Lake City, Utah at Jibe Cycleworks HQ.

Each wheel is tensioned with a 5% spoke variance, ensuring even tension across the rims and spokes for a stronger, truer build.

Wheels come pre-taped with tubeless valves for easy and quick tubeless tire installation.

Every Jibe wheel build starts with our X28 MTB or G24 gravel/road hubs, each featuring a 36-step ratchet system. Our ratchet mechanism has fewer parts, making it easier to service and simpler to maintain.

Weight Reduction

By using a single spring into the ratchet system, the hubs achieve a significant reduction in weight.

The X28 & G24 hubs feature our 36 tooth ratchet system which guarantees fast and consistent power transfer to your drivetrain, with minimal drag.

Choosing the right bearings is crucial for wheel performance. That's why we invest in high-grade, smooth rolling, low friction and quiet sealed cartridge bearings from the Japanese experts EZO.

The X28 MTB hubs now come with our brand new V2 ratchet system which features a rubber dampener built into the outer ratchet ring. This refines the sound of the hub and creates a tighter fit for the hub's internals which removes any unwanted play and increases reliability.

The ratchet rings are electroplated in a durable finish to reduce wear on the teeth and ensure smooth actuation.

Effortlessly swap driver bodies or perform routine maintenance thanks to our tool-less end cap and driver removal system.

Our Jibe Factory Asymmetrical Carbon Rims are incredibly lightweight yet extremely strong. We achieve this by using a blend of T700 and T800 carbon fibers. T700 offers high strength, while T800 provides a lighter, stiffer structure.

The off-center rim design offers more balanced spoke tension, resulting in a more durable wheel build. This combination of advanced materials and design ensures the rims are both lightweight and robust, delivering exceptional performance.

X28 Factory 29" MTB Wheels

Specifications:

G24 Factory 700c Gravel Wheels

Specifications:

A strategically placed lump on the rim bed reinforces the tires bead. This feature reduces burping when cornering and riding at lower pressures.

An R-shaped lip is molded on the rim for effortless tire installation and an enhanced tubeless seal.

Pro-grade vinyl. Color accurate print, laminated for durability, and precision cut.

Laminate finish in either Matte or Gloss.

Real Stealth decals are all black and have a dual-sheen finish with both matte and gloss to differentiate the graphics; the grey/black image is a depiction of this.

Foil decals that include mirror chrome will be produced in your selected finish and then mirror chrome will be applied on top.

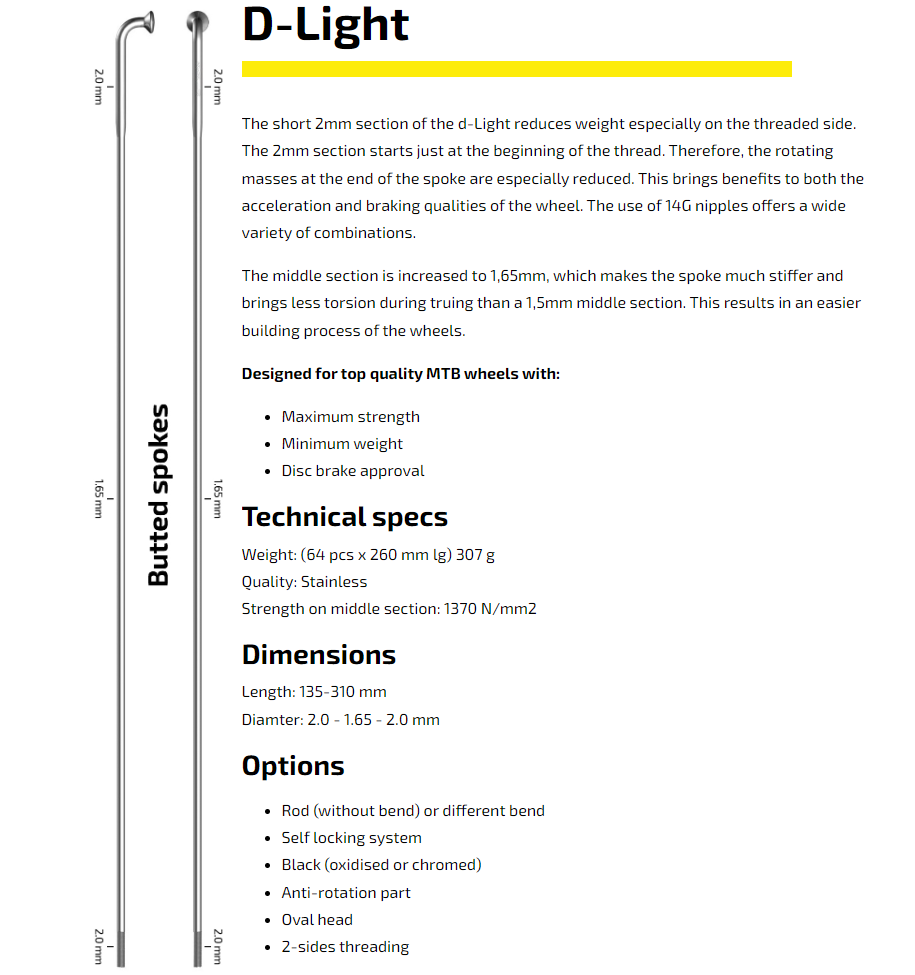

Sapim has a long-standing reputation for producing high-quality spokes trusted by professional wheel builders and cyclists worldwide. We use the D-Light spokes, which offers a incredible balance of strength and weight.

These are the only USA manufactured titanium spokes. They use the highest grade of titanium in the business which is what sets their quality above all other manufacturers internationally.

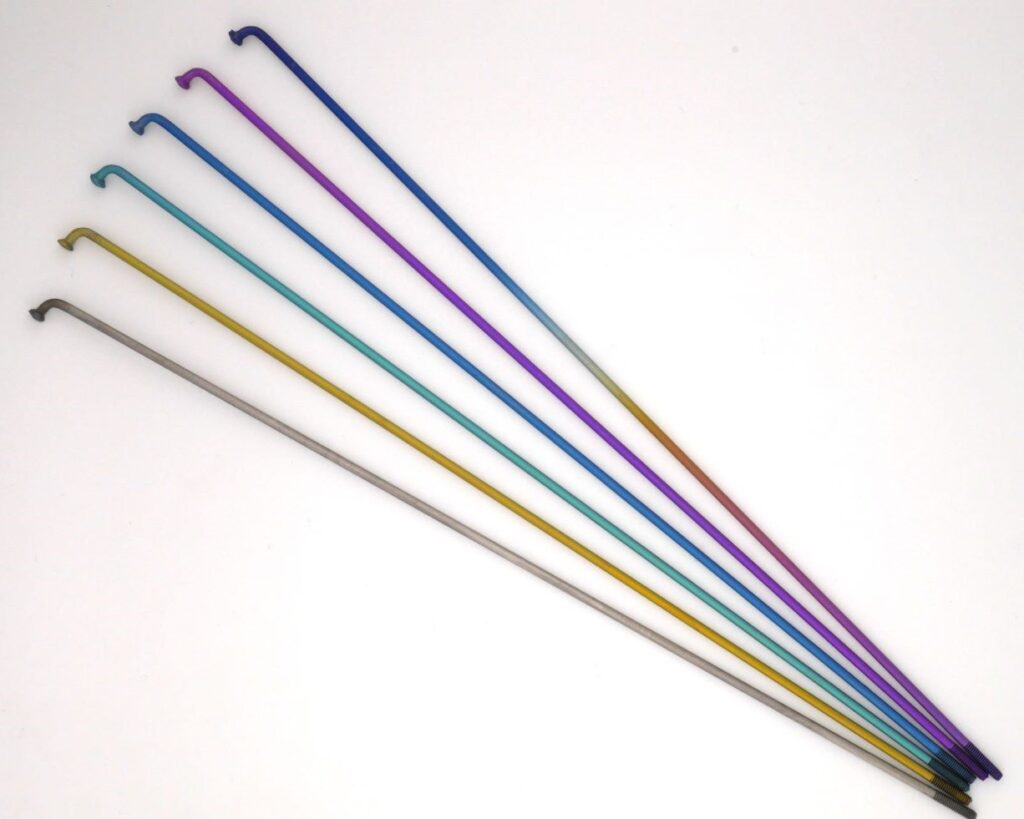

Gauge: 14G (2.0mm)

Head Options: J-Bend

Color Options: Natural, Rainbow, Gold, Turquoise, Blue, Purple.

Corrosion-Resistant –Won’t rust or corrode, even in wet or salty conditions.

Comfortable Ride – More flexibility absorbs road vibrations, improving comfort.

No Coating to Chip – Anodized finishes are part of the metal, unlike painted or coated stainless spokes.

Durable Against Fatigue – Less prone to long-term fatigue failure compared to stainless steel.

Long Lifespan – If properly tensioned, titanium spokes can last longer than stainless.